EN 71-1 ASTM F963 Light Testing Equipment , Toy Safety Sharp Edge Test Device

Product Details:

| Place of Origin: | China |

| Brand Name: | KingPo |

| Certification: | ISO17025 Calibration certificate |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | To be quoted |

| Packaging Details: | safety carton pack or plywood box |

| Delivery Time: | 7 working days |

| Payment Terms: | T/T |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| Standard: | 16CFR 1500,ISO 8124-1,GB 6675-2 | Dimensions: | 290x190x100 Mm (L X W X H) |

|---|---|---|---|

| Rotate Speed: | 1±0.08 Inches Per Second | Mandrel Hardness: | ≥40HR |

| Power: | Electronic | Weight: | 4 Kg |

| High Light: | temperature rise test equipment,led testing equipment |

||

Product Description

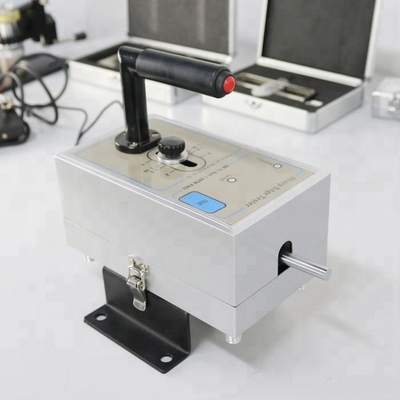

Toy Safety Sharp Edge Test Equipment/Tester, Sharp Edge Test Device

|

Sharp Edge Tester

|

|

|

Sharp Edge Tester used to determine that metal or glass edges on toys and other articles intended for use by children under 8 years of age, and such edges exposed in normal use or as a result of reasonably forseeable damage or abuse of such toys and articles, present a potential risk of injury by laceration or avulsion.

Standards: EN 71-1 ASTM F963 16CFR 1500 ISO 8124-1 GB 6675-2 |

0

1. The especially powerful value photoelectricity induction instruction function guarantees the test strength value fixed in 1. 35 pounds all long, and avoid the errors caused by different angle observation.

2. The especially powerful value external adjustment function, may extremely conveniently adjust the actual strength value to be consistent with the demonstration value, guarantee strength value calibration accuracy.

3. With 1.35 pounds calibration device, it can calibrate and adjust test force value at any time.

4. Test shaft is made of steel to and hardened processing

The surface should be smooth

The max force vertically applied to the axis when testing shoud be 1.35 LB.

5. Test shaft in its 75% turn routine, the tangent speed is 1.00±0.08 inches per second.

6. The test tape is pressure-sensitive PTFE (TFE) high temperature electrical insulation tape.

- The especially powerful value photoelectricity induction instruction function guarantees the test strength value fixed in 1. 35 pounds all long, and avoid the errors caused by different angle observation.

- The especially powerful value external adjustment function, may extremely conveniently adjust the actual strength value to be consistent with the demonstration value, guarantee strength value calibration accuracy.

Accessory

Thickness of adhesive tape on sharp edge:0.066-0.099mm

Width of adhesive tape on sharp edge:no less than 6mm

Cylindrical shaft:d=9.53mm

Charger:I/P 12A 50HZ 220V 25W O/P 15V 1.5A

Installation

1.test environment:under Greenhouse condition

2.This equipment is portable;place it on even area when using.

Operation

Sample preparation

Place it under standard temperature 20-25℃ with relative humidity 20-70% for at least 4h.

Step

1.Check if it can run normally with its amount of electricity before test

1.1Turn on the power(Fig 2) and then press handle switch(Fig 1)

(C)panel switch(Fig 1) (E)foot switch (Fig 1)

![]()

1.2 Keep 90±5°between axial lead and the toy edge,exert force on axis,when pilot light of force value is on and the red indication line meets requirement of 1.35LBS.

2.wrap a layer of PTFE adhesive tape anticlockwise at the end of axis;overlay of adhesive tape end<0.1 cun[a unit of length (=1/3 decimeter)]

3.support the toy edge right in the middle of PTFE adhesive tape and keep 90±5°with axial lead until pilot light of force value is on;press the starting switch or handle switch and step on the foot switch;make axis rotate a circle;then remove PTFE adhesive tape of sharp edge and observe it.If its cut length>12.7mm,then there is sharp edge and perform the next test.

4.Unplug the power cable(fig 2) as well as equipment’s when test finishes to avoid wastage of current.

![]()

![]()